Knowledge Base

CRATOLITE Infrared Emitters and Systems for industrial heat processes

Radiation, compared to convection and conduction, is the most powerful and efficient way of heating a material. In fact radiation does not need to come into direct contact with the surface of the products to be heated up and does not require the presence of any intermediary agent such as air.

Radiation operates with the transmission of energy through electromagnetic rays emitted by a heating element. The heating performance is influenced by the following criteria: heating element temperature, heated body capacity to absorb radiant heat, shape, position, and distance between the heated body and the heating source.

The infrared wavelengths generated by the IR Quartz Emitters range from 3.5 µm (medium wave) to 0.9 µm (short wave). Depending on the type of material to be heated, it is possible to use different types of IR wavelengths to reach the maximum propagation of energy and to obtain a faster and more efficient heating process.

The IR heaters, if compared with traditional heating systems that use hot air, emit more energy per unit surface, and this energy could be focused, concentrated, directed, and reflected just like light.

What Is Infrared Radiation?

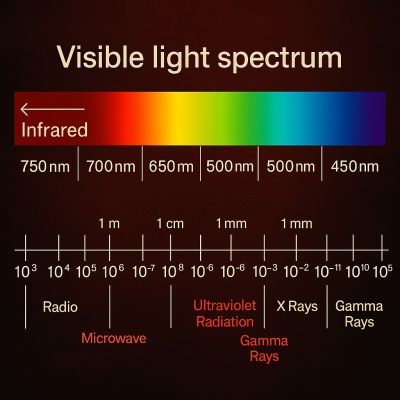

Infrared (IR) radiation is a form of electromagnetic radiation with wavelengths longer than visible light but shorter than microwaves—ranging from 700 nanometers (nm) to 1 millimeter (mm). Though invisible to the human eye, it is experienced as heat and is emitted by all objects above absolute zero.

| Region | Wavelength Range | Frequency Range |

|---|---|---|

| Near Infrared (NIR) | 700 nm–1.4 µm | 430 – 215 THz |

| Short-Wave IR (SWIR) | 1.4 µm–3µm | 215 – 100 THz |

| Fast Medium-Wave IR | ~1.6 µm | ~187 THz |

| Medium-Wave IR (MWIR) | 3 µm – 8 µm | 100 – 37 THz |

| Long-Wave IR (LWIR) | 8 µm – 15 µm | 37 – 20 THz |

| Far Infrared (FIR) | 15 µm–1 mm | 20 THz – 300 GHz |

Infrared and Temperature

The temperature of an object determines the peak wavelength of IR it emits, as described by Planck’s Law and Wien’s Displacement Law. For example:

- A hot metal surface (~1000°C) emits mostly in the shortwave IR range.

- A human body (~37°C) emits in the longwave IR range (~9–10 µm).

- Cooler objects emit in the far IR or even microwave range.

This is why shortwave IR lamps are used for high-temperature industrial processes, while longwave IR is ideal for gentle drying or food warming.

Infrared Over Time : Time–Temperature Behavior HA

In industrial heating, IR intensity over time is crucial:

- Shortwave IR reaches peak temperature in seconds—ideal for fast, high-energy processes.

- Medium and longwave IR have slower ramp-up but offer uniform, surface-level heating.

- Fast medium-wave IR bridges the gap—offering quick response with moderate penetration.

This time–temperature behavior is often visualized in IR emission curves, where intensity rises with temperature and shifts toward shorter wavelengths.

Why It Matters in Industry

Understanding these distinctions helps in:

- Selecting the right emitter for drying, curing, or forming

- Designing energy-efficient systems with minimal heat loss

- Targeting specific materials based on their IR absorption characteristics

Radiation, compared to convection and conduction, is the most powerful and efficient way of heating a material. In fact radiation does not need to come into direct contact with the surface of the products to be heated up and does not require the presence of any intermediary agent such as air.

Radiation operates with the transmission of energy through electromagnetic rays emitted by a heating element. The heating performance is influenced by the following criteria: heating element temperature, heated body capacity to absorb radiant heat, shape, position and distance between the heated body and the heating source.

The infrared wavelengths generated by the IR Quartz Emitters range from 3,5 µm (medium wave) to 0,9 µm (short wave). Depending on the type of material to be heated it is possible to use different types of IR wavelengths to reach the maximum propagation of energy and to obtain a faster and more efficient heating process.

The IR heaters, if compared with traditional heating systems that use the hot air, emit more energy for unit surface and this energy could be focused, concentrated, directed and reflected just like the light.

To further guarantee the quality of our products, we employ a dedicated team of experienced quality controllers. These experts, along with all our professionals, are selected for their talent and expertise in the industry. We are committed to continuous improvement through regular training, ensuring our team remains at the forefront of the latest technological advancements.

At Craftolite Solutions, we proactively assess the process heating and temperature control needs of a diverse clientele across various sectors. We also conduct ongoing research to stay informed about the evolving demands of different industries. This proactive approach has provided us with significant experience and proficiency in developing practical and effective solutions for our clients. Beyond offering a wide array of high-quality heaters in various configurations and voltage options, Craftolite Solutions is also committed to providing comprehensive service and support for all our product offerings.

To deliver the best quality, technically advanced products, we maintain a modern and efficient infrastructure. Our facility includes spacious manufacturing units, extensive warehouses, sophisticated quality control labs, efficient packaging and delivery departments, as well as dedicated sales and marketing teams. We have invested in the latest technology and modern equipment across all these units to enhance our production capabilities and create innovative products more effectively.

Our state-of-the-art facility is managed by a skilled team of experts who are proficient in their respective domains and ensure efficient operations. We continuously update our facility to incorporate technological advancements and adapt to evolving market demands. Our commitment is to provide our clients with competitive quality, innovative products, and exceptional value through our stable and well-maintained infrastructure.

Our Mission *

Core Values *

- Consider honesty as the key to a business’ trustworthiness and integrity.

- Always do the right thing to solve the customer’s problem.

- Perform all work with the highest level of excellence in mind.

Quality Assuarance

We are a client oriented company dedicated to providing our customers competitive and cost effective solutions. Each product in our inventory is of epitome quality, carefully engineered from fine quality material. The use of advanced technology and sophisticated machinery in the production of these products ensures their superior quality and finish. All the material employed in the manufacturing of our products is genuine and 100% original sourced from reliable vendors. We guarantee the production of these products in line with the industry parameters and standards for great value to our customers.

- Modern Infrastructure

- Cutting Edge Technology

- Trained Professionals

- Innovative Products

- Prompt Delivery

- Affordable Prices

We're here to help! Call Us Today!